Inspection

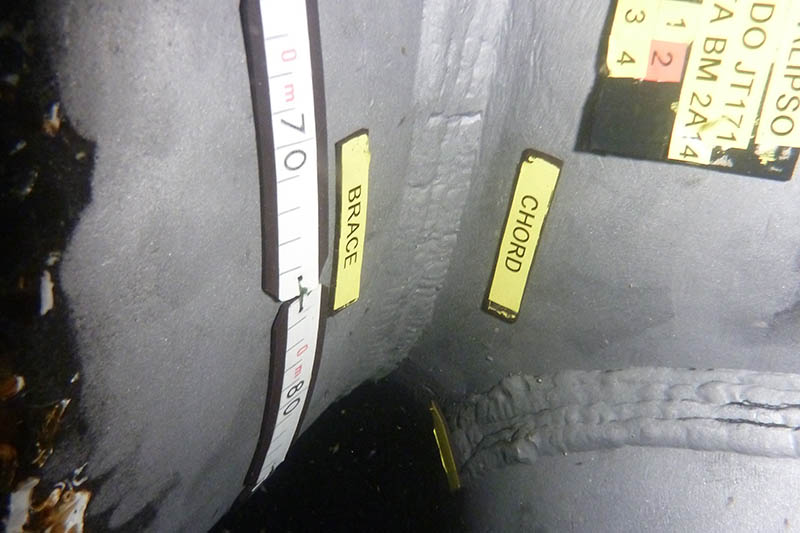

Inspection is a data-gathering task which helps to assess the structural integrity of a structure.

Inspection diving is not only based on visual methods such as photography, video and the diver’s own eyes, but also includes specialised activities such as:

-

Non destructive testing (NDT);

-

Corrosion damage inspection;

-

Cathodic protection surveys (anode inspection and electrical potential measurement)

-

Marine growth inspection and removal;

-

Scour and stability inspections;

-

Debris inspection and removal.

NDT requires considerable skill in operation and experience in interpretation, therefore all the diving personnel involved in NDT have received a sound training and a recognised qualification, supported by practical training and experience. Inspection projects are followed by a dedicated team of engineers qualified as underwater inspection controllers (CSWIP 3.4U), whose responsibility is to plan and co-ordinate the subsea inspection programme.

RANA owns state of the art equipment for the execution of non destructive testing, including:

-

Alternate Current Field Measurement (ACFM)

-

Magnetic Particle Inspection (MPI)

-

Ultrasonic Thickness Measurement (UT)

-

Cathodic Potential Gauges (CP)

-

Ultrasonic Flaw Detection and other systems

Maintenance and Repair

Maintenance and repair include a wide variety of tasks and skills, from cleaning to cutting and burning, pipeline connections, pipeline stabilisation, valves operating, air lifting, rigging, underwater grouting and so on.

Contact us

We have been our Client’s eyes and hands into the water for over 50 years.

We can assist you in complex projects and take full responsibility on critical packages to help you to reach your goals.

Share this page-

-

-